Automobile Industries

We have developed unique products catering to diverse industries, thus positioning ourselves as a single-stop moulding solutions provider.

Automobile Industry

Excel Plast strives to set the benchmark for quality and exceed customer expectations worldwide through commitment, dedication, innovation and quality-focused work in the automotive sector. Our rich expertise and unique capabilities in the automotive sector helps us to bring in repeat business, while ensuring better Return on Investment (ROI).

Our Capabilities

Technology Expertise

Excel Plast delivers latest technologies infused with ethical business strategies. Our people are our strength. More than technology and infrastructure, the quality of our people makes us unique and stand apart.

Systematic Process

Effective control plans and procedures are formulated for incoming material. Systematic sampling, in-house testing and inspection facilities further strengthen these controls.

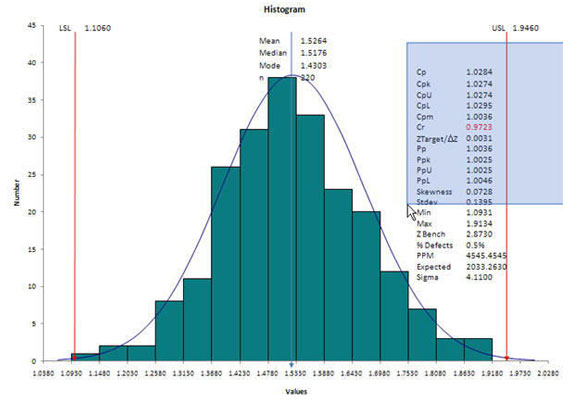

Constant Monitoring and Analysis

Statistical Process Control (SPC) techniques such as X/R charts for dimensional controls and p-charts for attribute characteristics are utilized for effective monitoring and analysis. Our process capability is assessed by maintaining CPK of 1.67 min. for all significant characteristics.

Corrective & Preventive Tools

Tools such as 8D technique, 5 Why analysis, ISHIKAWA diagrams, Drill Deep Worksheets, etc. are being utilized for problem solving by implementing appropriate corrective and preventive actions.

Control Plans

Every stage of manufacturing process is efficiently planned and strictly implemented with respect to machines, materials, men and environment.

Quality Focus

- Customer PPM is maintained below 100 collectively.

- Identifying 'Pass Through Characteristics' for critical parts and Poka-Yoke implementation for all such parameters for prevention and detection.

- Proper and well defined reaction plan for non-conforming products.

- Operating team facilitates regular, quality-focused in-house training for all employees.

- ISO/TS -16949 Certification helps obtaining regular and repeat business from automotive sector.

- Implementation of 5S principles throughout the factory.

- Utilization of SMED concept considerably reduces the setting time.

- All the shifts strictly implements Process Audit and maintain process consistency for all running parts.

- Quality Awards:

- 'Best Performer Award' from ACMA through Rane Cluster.

- Three times 'Best Supplier Award' from Rane TRW.